Create a Drillhole Composite by Cut-off Grade

Compositing by cut-off grade is commonly used to summarize assay data into intervals above a specified value. A minimum interval length can also be specified along with internal dilution constraints.

The composited interval is calculated using a downhole running weighted average of consecutive samples that conform to the cut-off grade parameters. Cut-off grade composites can only be calculated for one assay column at a time.

Table Input

Table

The input table containing the grade data that controls compositing (the "primary" column). All downhole tables in the drillhole project are displayed in the drop-down list.

Column

The primary column containing the sample values by which the cut-off grade is determined. All numerical columns in the input table are displayed in the drop-down.

By default, only the selected primary column is composited. To composite additional numerical columns (e.g. other grade values), click the Filter button to select the columns to be processed and included in the output table. Ensure that the primary column and the compulsory HoleID, From and To columns remain selected.

Ensure that the primary column and the compulsory HoleID, From and To columns remain selected.

Composite Grade

Minimum Grade

This parameter has two functions:

- Any sample grades below this value are excluded from the downhole running average grade.

- Unless internal dilution has been specified, if the downhole running average grade falls below this value, the current composite terminates.

High Cut Grade

Any sample grades higher than the high cut grade are cut to the high cut grade.

Composite Distance

- None—The full length of all drillholes are composited, including short holes and short composites.

- Drill trace length—Composites (above the cut-off grade) shorter than this downhole length are excluded.

- Minimum Vertical Thickness—Composites (above the cut-off grade) shorter than this vertical height are excluded.

Internal Dilution

Samples above the cut-off grade are often separated by samples with low grade assay values. Due to restrictions such as minimum mining width, it can be necessary to include this material as part of a composite interval.

An internal dilution length and grade can be set so that low grade material can be included in a composite under specified conditions. If the low-grade material is above the internal dilution grade, it is included as part of the composite if it's cumulative length (for the current composite interval) is less than the specified internal dilution thickness (downhole length). Low grade material is not added to the end of a composite interval.

Internal dilution can be assessed as either an average (default) or as a minimum dilution grade. For example, if internal dilution is set to 5 m at 50 ppb with the Average option selected, an interval of 5 m at 63 ppb would be valid regardless of the actual sample values making up this interval. However, if the Average option is cleared and the 5 m at 63 ppb segment contained 1 m at 30 ppb, the interval would not be valid.

If a subgrade interval is encountered, the following logic is applied:

- If the interval grade is below cut-off but above internal dilution grade, add the interval length to the total contiguous internal dilution length and calculate the diluted composite grade.

- If the diluted composite grade is above the cut-off and the total contiguous length of dilution does not exceed the maximum dilution length, add to the current composite. Get the next interval.

- If total contiguous internal dilution length exceeds the maximum dilution length or the diluted composite grade is less than the cut-off, terminate the composite and discard intervals back to last interval above cut-off grade.

- Start the next composite at the next interval above the cut-off grade.

Working Example

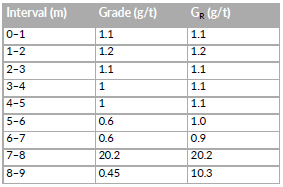

The Running Grade (GR) is the grade of a composite as its being composited down the hole. If the running grade falls below the minimum grade, the composite is cut back to the last intercept of minimum grade. For example, if:

Minimum Grade (GM) = 1 g/t

Internal Dilution Grade (GD) = 0.5 g/t

Internal Dilution Thickness (TD) = 5 m

In the table above we observe that a 5 m at 1.1 g/t composite would be created because the internal dilution (5–7 m) is not included this is due to the fact that the running grade GR dropped below the minimum grade at interval 6–7 m.

Edge Grade

Specifying an edge grade allows the application of edge padding when downhole compositing. The Edge Grade value (GE) should be set between the Internal Dilution Grade (GD) and Minimum Grade (GM) values. Edge Grade can only be used when Internal Dilution is applied. The maximum Edge Grade thickness TE uses the value set for the Internal Dilution thickness.

Edge padding allows a composite ending in a valid internal dilution interval to be carried through to a sample >=GM if the intervening interval meets the Edge Grade requirements and the overall running grade >= GM throughout.

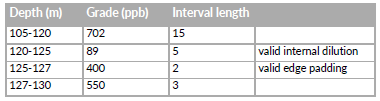

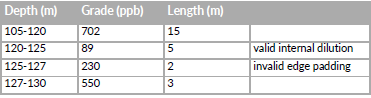

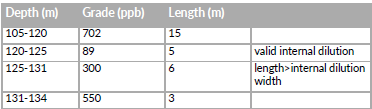

Working example

GM = 500 ppb

GD = 50 ppb

GE = 250 ppb

TE = 5 m

Assuming that the running grade is >= 500 ppb across the composite, the following interval would be treated as a continuous composite:

The following interval would finish the composite at 120 m:

The following interval would also finish the composite at 120 m:

Table Output

Interval Column

A new column (default name "Interval") is added to the output table containing the downhole length of each composited interval. An existing field cannot be specified.

Composite data is stored in a new table. The new composite table is named using the original downhole table name with a default suffix of "_comp". The suffix can be changed to any user specific name.

By default, only the selected "primary" column is composited. Use Filter option on the input table Column selection (above) to add extra columns to the output table. If additional fields are composited, modify the table suffix to show the primary compositing field, e.g. "_comp_Cu".

Activity Steps (without internal dilution)

- On the Drillhole ribbon tab, in the Analyse group, expand Composite and click Grade.

The Composite panel displays the Grade parameters.

- Select the drillholes.

- Configure the Data Handling Options if required.

- Click Data Handling Options.

The Data Handling Options window displays.

- Enter the Numeric Null Value.

- Select whether to Set all null values to.

If checked, enter a number.

- Select whether to Set all negative values to.

If checked, enter a number.

- Select whether to Multiple negative values to.

If checked, enter a number.

- Select whether to Set all zero values to.

If checked, enter a number.

- Select whether to Custom assign values from template table.

If checked, complete the following parameters:

- Select template table

- Assign element name field from the template table.

- Replace any occurrence of

- With a new value of

- Click OK.

- Click Data Handling Options.

- For the Table Input, select the Table containing the grade data that controls compositing (the "primary" column).

All downhole tables in the drillhole project are displayed in the drop-down list.

- Select the Column. This is the primary column containing the sample values by which the cut-off grade is determined.

- Configure the Composite Grade if required.

- Enter the Minimum grade. Sample grades below this value are excluded from the downhole running average grade.

- Select whether to High cut grade.

If checked, enter a number for the grade.

- Select whether to Composite Distance from:

- None—Default

- Drill Trace length

If selected, enter a value in meters.

- Vertical thickness

If selected, enter a value in meters.

- Configure the Table Output where required.

- Enter the Interval column name.

- Enter the Table suffix.

- Click Generate.

Activity Steps (with internal dilution)

- On the Drillhole ribbon tab, in the Analyse group, expand Composite and click Grade.

The Composite panel displays the Grade parameters.

- Select all the drillholes.

- Configure the Data Handling Options if required.

- Click Data Handling Options.

The Data Handling Options window displays.

- Enter the Numeric Null Value.

- Select whether to Set all null values to.

If checked, enter a number.

- Select whether to Set all negative values to.

If checked, enter a number.

- Select whether to Multiple negative values to.

If checked, enter a number.

- Select whether to Set all zero values to.

If checked, enter a number.

- Select whether to Custom assign values from template table.

If checked, complete the following parameters:

- Select template table

- Assign element name field from the template table.

- Replace any occurrence of

- With a new value of

- Click OK.

- Click Data Handling Options.

- For the Table Input, select the Table containing the grade data that controls compositing (the "primary" column).

All downhole tables in the drillhole project are displayed in the drop-down list.

- Select the Column. This is the primary column containing the sample values by which the cut-off grade is determined.

- Configure the Composite Grade if required.

- Enter the Minimum grade. Any sample grades below this value are excluded from the downhole running average grade.

- Select whether to High cut grade.

If checked, enter a number for the grade.

- Select whether to Composite Distance from:

- None—Default

- Drill Trace length

If selected, enter a value in meters.

- Vertical thickness

If selected, enter a value in meters.

- Configure the Internal Dilution as required.

Note: If the low-grade material is above the grade that is selected, it is included as part of the composite if it's cumulative length (for the current composite interval) is less than the specified internal dilution thickness (downhole length). Low grade material is not added to the end of a composite interval.

- Select Internal Dilution and enter interval thickness in meters.

- Enter the grade @ the specified interval and select whether this is the Average grade.

- Select whether there is an Edge grade.

If checked, enter the number.

- Configure the Table Output if required.

- Enter the Interval column name. Default: Interval

- Enter the Table suffix. Default: _comp

- Click Generate.