Processes and Products

Processes (sometimes called products) are one of the key building blocks in developing a schedule model in Minemax Scheduler. A process may be used in a model because there are physical capacity constraints that need to be considered, for example tonnes or ore going to a mill. Another reason for including a process is that it may be necessary to report on some aspect of a mine schedule but not necessarily constrain it, for example the tonnes of oxide material going to a mill. Another reporting example is tonnes of material going to a waste dump may not need to be constrained, but it likely needs to be reported or tracked. Trucking might be defined as a separate process to constrain waste movement or total movement, but the tonnes of material going to one or more waste dumps can still be reported through respective process definitions.

Blocks contribute to each process through values called process ratios. Process ratios are normally numbers between zero and one which when multiplied by the tonnes of a block give a quantity associated with the contribution of a block to the process. For example, a block which is predetermined to be ore and will go to the mill based on its grade would have a mill process ratio of 1.0. The summation of these quantities for all block which are scheduled in a common time period are used in Minemax Scheduler's constraint engine to ensure constraints related with processes are not broken.

In Minemax Scheduler there are 5 different types of processes for modelling.

- Mining

- Downstream

- Calculated

- Dump Volume

- Downstream Dump Volume

Mining

A mining process is one where there are no further decisions associated with a block other than when it is to be mined. Mining processes are predetermined decisions that say when a block is mined in a certain period, it uses or contributes to certain amounts of processes according to the process ratios of the block for those processes.

When there are single predetermined destinations for all blocks, typically all processes will be mining processes.

Downstream

A downstream process gets its name from the fact that it is normally associated with physical processes which are downstream from the core physical mining (load and haul) process. The specific way in which they differ from mining processes is that they are used to represent decisions related to how material is processed, treated or transported. For example, mill or heap leach may be two alternative methods for processing. In this instance mill and leach would be defined as downstream processes and would have a decision point associated with them through what is known as a process split. At the time of running the optimization, a decision would be made on when to mine a block and there would be another decision on whether the block is to be sent to mill or leach. To model this accurately, recoveries and processing costs of mill and leach would also be defined.

Calculated

A calculated process is an advanced type of process that enables constraints to be set on combinations of other processes. Furthermore, it enables the specification of particular material movements associated with the other processes. To understand this, it may be helpful to first gain a basic understanding of what happens with processes, blocks, process ratios and constraints during an optimization.

For process capacity constraints, minimum and maximum limits are entered by a user in the Minemax Scheduler GUI. Minemax Scheduler uses this information in the construction of an mathematical linear program (lp) model (actually milp). Variables in the lp model include the following key three scheduling decisions for a given time period that correspond to possible material transfer paths within Scheduler:

- The proportion of a block that is mined and is stockpiled for processing in future time periods.

- The proportion of a block that is mined and is processed in the current time period.

- The proportion of a blended stockpile (typically built from earlier time periods) that is reclaimed for processing in the current time period.

The important thing to understand about these variables is that only 2 and 3 are considered in process capacity constraints. The ramification of this on a holistic treatment of equipment constraints can be easily seen. If a TotalTruckHours process is defined to model truck hours and a maximum limit is entered, that maximum will only constrain the material going directly from both the pit to the process and the stockpile to the process and will NOT include the material from the pit to the stockpile. This is where calculated processes can play an important role.

Component processes of calculated processes have 3 movement types that can be included in calculated process calculations:

- Direct feed

- Stockpile

- Reclaim

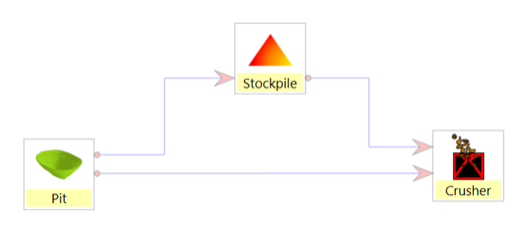

For the above trucking example, DirectTrucking, StockpileTrucking and ReclaimTrucking can be defined as regular mining processes. For a given block, the process ratio for DirectTrucking and StockpileTrucking would be related to the truck hours required for each of these processes respectively. The process ratio for ReclaimTrucking would have to account for the particular stockpile a block would go to if stockpiled and the truck hours required for that block to be taken from that stockpile to the Crusher.

A TotalTruckHours which is a calculated process would have DirectTrucking, StockpileTrucking and ReclaimTrucking as its component processes. Now if a block is directly sent to the crusher, the StockpileTrucking and ReclaimTrucking amounts should not be used in the TotalTruckHours constraint. To achieve this, the DirectTrucking has the direct feed movement type enabled, StockpileTrucking has the stockpile movement type enabled and ReclaimTrucking has the reclaim movement type enabled.

These concepts may be difficult to understand initially, but become quite powerful once they are understood.

Waste

When stockpiles are used, material that is never intended to be processed (waste) and goes to a waste dump is identified as such by being the last process in the list of processes. Often the name of that process is Waste. While it is possible to have blocks which are partially ore and partially waste, when stockpiles are present, it is best to keep waste as separate blocks.

When a block is sent to the stockpile, the tonnes sent is calculated as follows:

Where:

- BlockTonnes is the total original tonnes in a block.

- WastePR is the process ratio of the last process (typically waste process).