Reconciliation Metrics and Comparison Values

Understanding the Mine Value Chain and Reconciliation

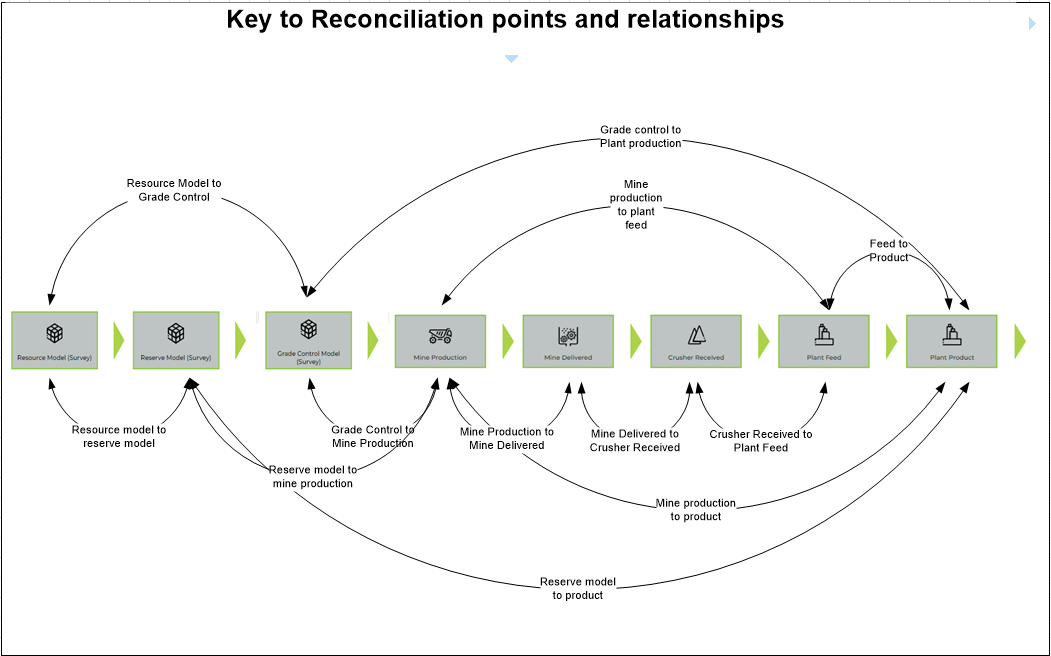

The diagram above illustrates the Mining Value Chain, which can extend all the way through to customer delivery. This highlights the key reconciliation points commonly analysed across mining operations, showing how different disciplines - geology, mining, processing, and metallurgy - work together to measure and understand a mine's performance.

Reconciliation across these stages is essential for verifying that material and metal movements align with expectations. However, in practice, this process can often be complex, fragmented, and time-consuming, involving multiple data sources and systems that do not always connect seamlessly.

Understanding Your Site’s Material Movement Flow

Before implementing Reconcilor, it is important to have a clear understanding of how material moves through your operation — from the resource model through to the final product.

This flow defines the physical and data pathways that underpin reconciliation, and every site's configuration is slightly different.

Mapping your material movement flow helps you:

- Identify all reconciliation points and data hand-offs.

- Understand where losses, stockpiles, or reclassifications may occur.

- Confirm that each system involved in tracking tonnes and grades is accurately represented within Reconcilor.

Reconcilor is configured around this flow, ensuring that your site's unique processes - such as multiple ore sources, blended stockpiles, or plant treatment - are captured correctly.

This foundation ensures that all subsequent reconciliation metrics and reports reflect the true movement of material across your mining value chain.

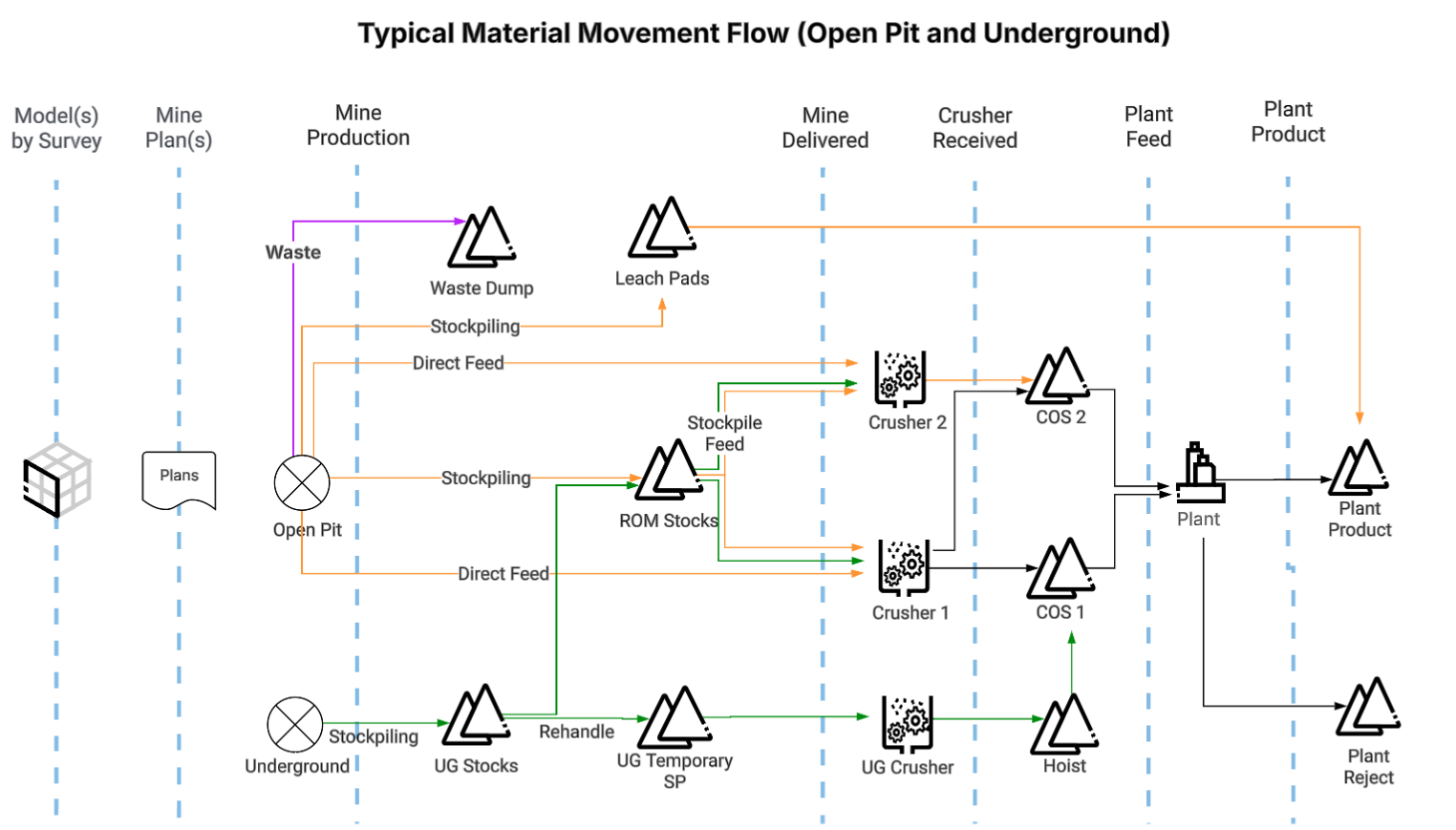

Example: Typical Material Movement Flow (Open Pit and Underground)

This example illustrates how material moves from geological models and mine plans through production, crushing, processing, and product output.

It represents a typical mining operation that includes both open pit and underground sources, stockpiling, re-handling, and multiple crushing and plant feed routes.

Your site’s configuration may vary depending on its layout, processing routes, and reporting requirements.

Tip: Use this diagram as a reference when defining your site’s own material movement flow.

The goal is to identify the key transfer points where tonnes and grades should be reconciled.

Diagram Legend and Definitions

Flow Colours

| Flow Colour | Definition |

|---|---|

| Orange arrows | Open pit or leach material flow |

| Green arrows | Underground material flow |

| Purple arrows | Waste material flow |

| Black arrows | General or neutral flow between processing stages |

Flow Phases and Elements

| Phase or Element | Definition |

|---|---|

| Model(s) by Survey | Digital geological and block models that represent the orebody — including resource, reserve, and grade control models — updated from survey data. |

| Mine Plan(s) | Short-, medium-, and long-term mine plans (LTP, MTP, STP) defining where and when material will be mined based on model data. |

| Mine Production |

Stages involved in mining, handling, and preparing ore before it is sent for processing.

|

| Mine Delivered | Material transported from the mine to the crusher or ROM pad, typically measured at delivery points for reconciliation. |

| Crusher Received |

Points where ore is received and crushed before entering the plant.

|

| Plant Feed | Ore that has been crushed and is ready to enter the processing plant. This represents a key reconciliation point for comparing mined and processed tonnes and grades. |

| Plant Product | The final, saleable output from the processing plant — such as concentrate, dore, or refined metal. |

| Plant Reject | By-products or waste material from processing, including tailings or residues that do not contribute to the final product. |

How Reconcilor Simplifies the Process

Reconcilor brings order and clarity to this complexity. The system begins by creating a conceptual model of your operation, tailored specifically to your site. This model integrates all relevant data, including:

- Resource and reserve models

- Grade control and production data

- Material movement and stockpile data

- Weightometer, crusher, and plant feed data

- Processing and product output information

By consolidating these inputs, Reconcilor establishes a single, connected data environment for reconciliation. This enables transparent comparisons between key points in the value chain - such as resource to reserve, mine to mill, and plant feed to product - ensuring that every tonne and its product can be accounted for with confidence.

The result is a clearer understanding of performance, improved data reliability, and actionable insights to drive better operational decisions.

Reconciliation Metrics and Comparison Values

Once your site’s conceptual model is established, Reconcilor enables you to define and measure key reconciliation metrics that quantify performance at each stage of the mining value chain. These metrics compare material movements, grades, and metal contents between successive stages - for example, Resource to Reserve, Mine to Mill or Plant Feed to Product.

Each comparison highlights how effectively material is being converted from one stage to the next, identifying losses, dilution, or discrepancies in both tonnes and metal content. By analysing these relationships, you can uncover root causes of variance, validate operational assumptions, and improve future planning and forecasting.

Reconcilor presents these metrics through configurable dashboards and reports, allowing you to visualise trends, drill into detail, and benchmark performance over time. This data-driven approach transforms reconciliation from a retrospective reporting exercise into a proactive management tool for continuous improvement.