|

Multimine Scheduler An overview of Multimine Scheduler |

Multimine Scheduler (MMS)

Multimine Scheduler extends the functionality of single-mine projects to simultaneous optimization of several mines represented by distinct block models.

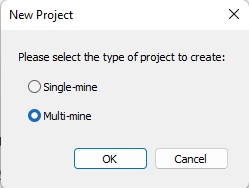

Multimine support for a project is decided at the point of project creation; you get to choose a single or multiple mine project:

Multimine projects have the same case study structure and use the same optimization, reporting and visualization tools as single mine projects.

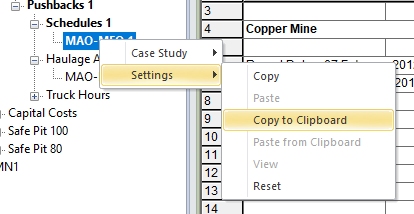

You can work on a Multimine project, starting

with importing geological models (at least two) all the way from economic

model generation through pit optimization, pushbacks, scheduling, to material

allocation and mine flow optimizations. A Multimine project is completely

independent of a single mine project but you can transfer information

between the two document types with simple cut and paste commands available

on the Project Map control bar,

e.g.:

To create a Multimine project in Studio NPVS or Studio RMS (Multimine is not available for Studio Maxipit), you will need a dedicated Multimine (MMS) license. With an MMS license installed, the Multi-mine option becomes available during project creation.

Multimine Scheduler Functions

-

Find optimum pit limits for each mine and an All Mines block by block extraction sequence for given geological and economic parameters using one of the following methods:

-

-

Lerchs-Grossmann search to locate the economic limits to open pit and generate NPV extraction sequence that optimizes NPV from all mines.

-

Resource based search to find optimum All Mines blended pit (collection of pits from individual mines that jointly meet blending targets) and blended extraction sequence.

-

-

Convert the extraction sequence resulting from pit optimization into practical pushbacks for each mine by applying user defined criteria like minimum pushback size and minimum access width and an All Mines pushback based extraction sequence.

-

Schedule the pushbacks, or any other pit sequence, from mines to meet user defined mining, haulage, processing and blending targets. A haulage simulation model can be defined with multiple ore and waste destinations which permits a one-step optimization of the life of mine haulage plan. The optimal schedule is defined as another All Mines extraction sequence.

-

Reevaluate the schedule with Material Allocation Optimizer that accounts for time varying economic parameters, stockpiles and multiple blended products.

-

Reevaluate the schedule with Mine Flow Optimizer which adds cutoff grade optimization functionality to MAO.

Multimine Scheduler Input

-

Block models defining geological and geochemical properties of the mineral deposits; at least two models and up to as many as your computer’s resources will allow.

-

Economic parameters such as metal prices, mining and processing costs, metal recoveries, etc. The economic parameters are mine specific and can vary between mines.

-

Optionally, an externally designed sequence of pushbacks to be scheduled. For any mine, you can import pushbacks from an external application or from an NPVS 4 document. Multimine Scheduler can process any mixture of internally generated and imported pushbacks.

Multimine Scheduler Output

-

Mine specific pit topographies (surfaces) viewable and exportable as 3D objects, contours and block model fields. In addition to Lerchs-Grossmann ultimate pits and phases, pushbacks and the scheduler annual pits, Multimine Scheduler can generate any configuration of intermediate pits from all extraction sequences it produces.

-

Customizable spreadsheet reports and charts including all mines reports, pit specific reports, bench reserves (mine specific only) and all mines and mine specific grade curves.

-

Viewable and exportable block models with cost/revenue information and pit definitions. Mine Flow Optimizer, like Material Allocation Optimizer, builds a parcel model with each parcel (subcell) tagged by its destination (processing method, stockpile, blended product).

Optimization Tools

-

Economic Model: calculate revenues, costs, metal recoveries and overall block values for multiple products (metals), multiple rock types and multiple processing methods. The application provides support for spreadsheet type formulas for cost and recovery calculations. The economic parameters can vary from mine to mine.

-

LG Pit Optimizer: generate Lerchs-Grossmann ultimate pit and phases for each mine, and an all mines extraction sequence maximizing NPV over all mines.

-

Blended Pit Optimizer: generate optimal all mines blended pit (collection of pits from individual mines that jointly meet blending targets) within the mine specific maximum resource or LG ultimate pits, and an optimal blended extraction sequence. The extraction sequence can be used to obtain intermediate blended pits.

-

Pushback Generator: create a sequence of practical pushbacks for each mine and all mines pushback based extraction sequence by applying user defined criteria to the all mines extraction sequence generated by the pit optimizer.

-

Scheduler: find year-by-year an all mines schedule for mining the pushbacks or any other sequence of pits to meet targets like constant ore output, strip ratios, contamination control, blending etc. The resulting schedule is presented as an all mines block by block extraction sequence with each block tagged by year in which it will be mined. Note that multimine scheduling makes sense only if at least one target binds all the mines together; for example, a global metal output.

-

Haulage Analysis: define mine specific ore and waste destinations for haulage simulation model and schedule directly by truck hours per year. Note that although destinations are defined separately for each mine, you can set a global multimine truck hours target.

-

Material Allocation Optimizer: optimize allocation of inputs (rock types divided into grade classes, stockpiles, external sources) to destinations (processing methods, blended products, stockpiles) subject to quality constraints, blending constraints etc. Multimine Scheduler treats rock types from different mines as separate inputs but automatically aggregates elements, products and processing methods from all mines bearing the same names.

-

Mine Flow Optimizer: maximize all mines NPV by adjusting annual mining rates, which is equivalent to cutoff grade optimization, simultaneously allocating material to their optimum destinations.

Reports and Charts

Multimine Scheduler displays reports in built-in spreadsheets. These reports include fixed content optimization summaries and customizable reports on optimization results, bench reserves and grade curves. All summaries and reports include mine specific and all mines parts. Customization options include:

-

Selecting which data columns to display and the order in which they are to be displayed.

-

Defining new data columns with spreadsheet type formulas.

-

Modifying report look in ways typical for spreadsheet applications.

Any report data column or a combination of columns can be charted with the built in charting application.

Visualization

Multimine Scheduler supports visualization in 2D and 3D of all objects it generates and imports including block models, surfaces and digitized outlines. All objects are mine-specific. The 3D window allows you to manipulate the objects visually and playback animations and sequences, query the objects for data, animate and insert smart plot items like text boxes, scale bars, coordinate grids etc. All surfaces can be rendered in the usual 3D manner and contoured.

External Data Sources

Block models with geological data, surfaces and polygonal outlines can be imported from many external sources like text files, data bases tables, spreadsheets, AutoCAD etc. Special facilities are provided for importing and refreshing data from Datamine and Medsystem files. All objects generated by Multimine Scheduler can be exported to third party applications.

Multimine dependencies

If you're running a Multimine project, the Scheduler Settings dialog will display an Inter Mine Dependencies panel in place of a Pushback Dependencies panel.

Where multiple mine operations are underway, it is common for mines to be mined consecutively or with a fixed time lag.

For example, mine B starts a few years before completing mine A, and ore will be crushed at one mine at a time (crusher will be moved from Mine A to Mine B). Any ore mined from Mine B while Mine A is in operation needs to be stockpiled.

The Inter Mine Dependencies panel allows you to define pushback dependencies between mines of a Multimine project. More...

|

|

Related Topics |

|

|

Life

of Mine Planning |

Copyright © Datamine Corporate Limited

JMN 20065_01_EN