|

|

A detailed overview of MSO's Slice Method |

MSO - Slice Method

Introduction

With this method, MSO generates thin slices (seed-slices) across the mineralized zones that are aggregated into seed-shapes that satisfy stope and pillar width constraints and cut-off. This is why this is known as the "Slice Method". This method optimizes strike-by-height/width projections of stope-shapes in the transverse orebody direction (width / thickness), depending on its orientation (vertical or horizontal).

Slice method frameworks are available in either Standard or Advanced types.

The framework in which MSO operates can be defined independently for each scenario you create, and is based on the following key criteria:

- The stope generation method (currently, the Slice method is supported)

- The Stope Arrangement settings (vertical or horizontal)

- The Stope Alignment settings (along strike or across strike)

This shape framework is defined using the Shape panel.

MSO generates thin slices (seed-slices) across the mineralized zones that are aggregated into seed-shapes that satisfy stope and pillar width constraints and cut-off. This is known as the "Slice Method". This method optimizes strike-by-height/width projections of stope-shapes in the transverse orebody direction (width/thickness), depending on its orientation (vertical or horizontal).

The Slice Method generates and evaluates thin slices across the mineralized zones that are aggregated into seed-shapes (looking at all possible permutations) that satisfy stope and pillar width constraints. The seed-shapes are then annealed to the final optimized stope-shape satisfying the stope and pillar width, stope geometry constraints (e.g. wall dips angles, strike twist, etc.), and other miscellaneous constraints (e.g. zone mixing, exclusion zones, etc.). The result is a set of stope-shapes constrained to the basic limitations of the envisaged mining method.

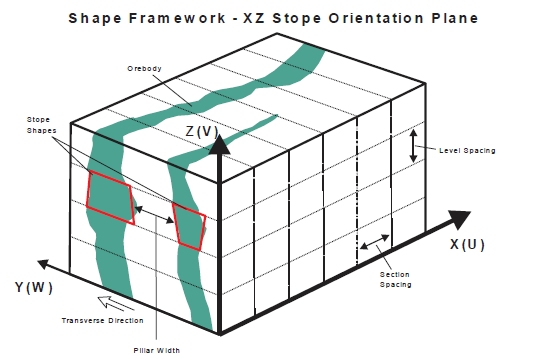

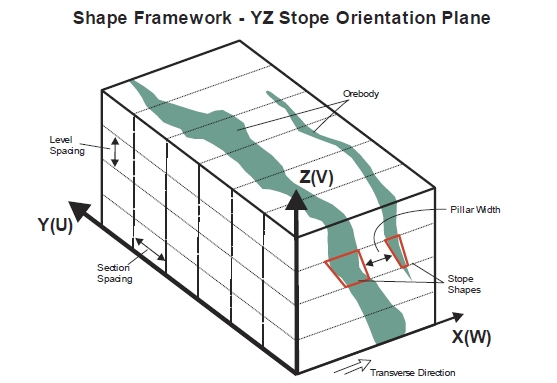

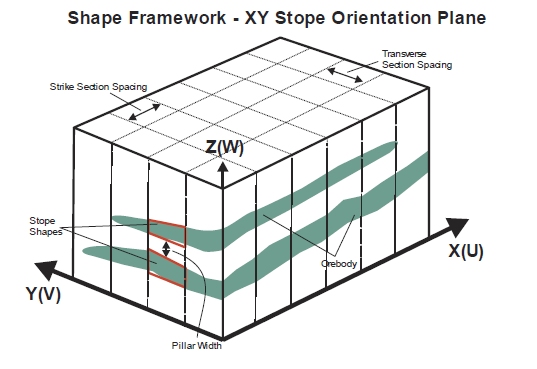

The Slice Method can be applied in all four stope-shape framework orientations, vertically for (XZ|YZ) and horizontally for (XY|YX). The correct framework orientation to apply is dictated by the orebody orientation within the block model.

The stope sections (U-axis) may be regularly spaced or irregularly spaced. At the same time, the stope levels (V-axis) may be regularly spaced, irregularly spaced or irregularly spaced with variable gradient.

The faces of the stope-shapes produced are sectional outlines defined by four points. For orebodies with vertical orientation this will be two on the floor and two on the back. For orebodies with horizontal orientation this will be two on each of the stope end faces.

The points lay in the stope-shape UV-axis plane and the projection of the face is either a rectangle or a trapezoid where the opposite sides are parallel. Rectangular and trapezoidal shapes are special cases of 4 sided polygons. These are commonly referred to as quadrilaterals in SSO. The quadrilaterals form a tube-shape when extruded in the transverse direction representing the stope-shape W-axis.

More about Shape Frameworks...

Comparison with the Prism Method

As described below, the Slice method can be applied in four stope-shape framework orientations, vertically for (XZ|YZ) and horizontally for (XY|YX)., the Prism method supports for just two orientations in total; XZ and YZ.

More about the Prism method...

Slice Method in Detail

The Slice Method generates and evaluates thin slices across the mineralized zones that are aggregated into seed-shapes (looking at all possible permutations) that satisfy stope and pillar width constraints. The seed-shapes are then annealed to the final optimized stope-shape satisfying the stope and pillar width, stope geometry constraints (e.g. wall dips angles, strike twist, etc.), and other miscellaneous constraints (e.g. zone mixing, exclusion zones, etc.). The result is a set of stope-shapes constrained to the basic limitations of the envisaged mining method.

More about the Slice Method...

Slice Method frameworks are sub-categorized as:

- Vertical;

XZ or YZ orebody orientations.

Vertical XZ example:

Vertical YZ example:

- Horizontal;

XY or YX orebody orientations. The selection of YX over XY will

be dictated by the ability to have greater control over roof and

floor angles along the V-axis.

Horizontal XY example:

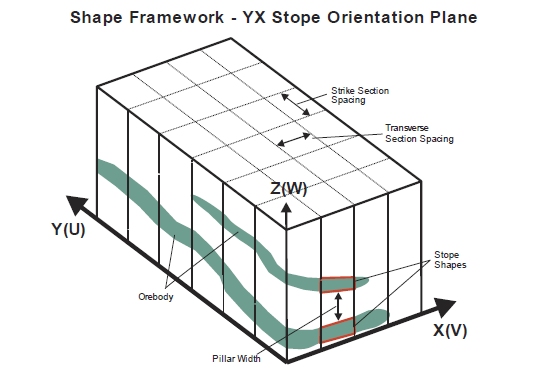

Horizontal YX example:

The Slice Method can be applied in all stope-shape framework orientations, vertically for (XZ|YZ) and horizontally for (XY|YX). The correct framework orientation to apply is dictated by the orebody orientation within the block model. The stope sections (U-axis) may be regularly spaced or irregularly spaced. At the same time, the stope levels (V-axis) may be regularly spaced, irregularly spaced or irregularly spaced with variable gradient.

The faces of the stope-shapes produced are sectional outlines defined by four points. For orebodies with vertical orientation this will be two on the floor and two on the back. For orebodies with horizontal orientation this will be two on each of the stope end faces.

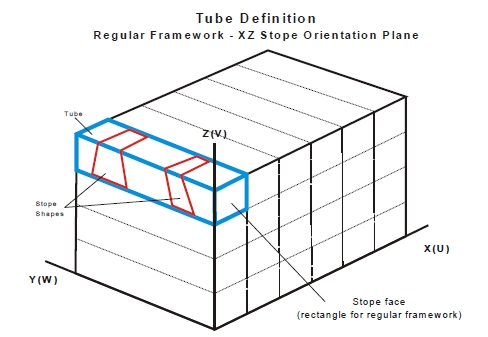

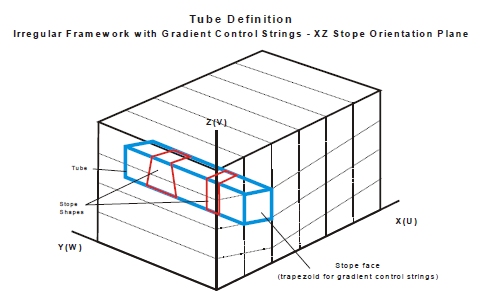

The points lay in the stope-shape UV-axis plane and the projection of the face is either a rectangle or a trapezoid where the opposite sides are parallel. Rectangular and trapezoidal shapes are special cases of 4 sided polygons. These are commonly referred to as quadrilaterals in MSO. The quadrilaterals form a tube-shape when extruded in the transverse direction representing the stope-shape W-axis.

The Slice Method XZ | YZ | XY | YX framework orientations can be mapped or visualized with a generic naming convention related to the axis direction:

- U-axis is the primary “strike” direction of the stope-shapes (i.e. length),

- V-axis is the secondary “vertical” direction of the stope-shapes (i.e. height for vertical / width for horizontal),

The first letter of the framework orientation is the U direction and the second is the V direction. So for example with the XZ orientation, X is the U-axis and Z is the V-axis.

Slice frameworks for Vertical and Horizontal orientations are further sub-categorized as:

- Regular frameworks, where both axes use fixed intervals (the U-axis intervals and V-axis intervals are fixed) – like having fixed section spacing and fixed level spacing for vertical orientations or fixed strike sections and fixed wall spacing for horizontal orientations.

- Irregular frameworks; where either or both of the U and V-axis intervals is variable. For example like having 4x25m levels and 1x15m sill pillar level for a mine block covering 115m vertical extent which is repeated, or like having 15m primary and 20m secondary stopes along strike (for vertical orientations).

- User Defined frameworks; where coordinates are provided to define long section (U, V) dimensions of the stope-shape geometry. The coordinates can represent either rectangular shapes (orthogonal), or trapezoidal or quadrilateral shapes (non-orthogonal).

MSO framework orientations are defined using the Orientation panel.

Irregular Slice Method frameworks can also use control strings for defining variable level elevations (gradients for vertical orientations) or variable side-wall spacing – likened to topographic contours (for horizontal orientations).

The framework and stope geometry are described in the following terms:

- stope orientation plane, a two dimensional plane defined by the framework orientation (XZ, YZ, XY or YX)

- stope face, the (fixed) U and V dimensions of the stope-shape

- The tube, a three-dimensional volume defined by the stope face and the framework extents in the W direction (transverse). The seed-slice, seed-shape

Slice Method - Tube Definitions

The following depicts the tube shape within regular and irregular stope-shape frameworks for the Slice method. The controls for stope-shape geometry are located on the Shape panel, with additional controls found in both the Controls and Refinement panels.

|

|

Related Topics |

|

|

MSO

Introduction

MSO Shape Framework Concept MSO Prism Method Scenarios |