Scheduling Pushbacks

Studio NPVS has, up to this point, produced a series of extraction sequences that indicate the order in which to mine (where and when) logically according to all of the parameters that have been taken into account (value considerations such as those used to generate the Ultimate Pit OES and practical considerations such as those encompassed by the Pushback OES).

The pushback scheduler module (commonly referred to simply as the 'Scheduler') performs this task. The objective of the Scheduler is to find a practical schedule for mining the pushbacks. For the highest NPV it would theoretically be best to mine the pushbacks in sequence, one at a time. Unfortunately, this strategy is rarely practical because it does not satisfy targets such as ensuring a steady output of ore at manageable strip ratios, nor does it satisfy other possible requirements like ore blending or contamination control.

The objective is to find a practical sequence maximizing NPV when mining the pushbacks using the following inputs:

- Pushback OES

- Scheduling targets (primary and secondary)

- Pushback maximum sinking rate

- Bench lags between pushbacks

The scheduler allows mining of two or more pushbacks at the same time while targeting high NPV and other objectives.

The scheduler considers the impact on all future periods; it does not just schedule one period at a time

The scheduler provides much more practical mining strategies by allowing for mining two or more pushbacks at the same time while targeting these other objectives. Like the OES generator the scheduler uses the concept of benches, or more correctly pushback-benches, within a dynamic programming model based on partial enumeration of potential solutions. This approach builds multiple solutions meeting the targets such as ore tonnes and truck hours (see Appendix 1), eventually selecting the solution with best NPV or most closely tracking the ideal value of a chosen target.

The system can target any variables or combinations of variables that are defined by mathematical expressions of attributes of the economic block model. Therefore the schedule can be set to target mining rates, truck hours, mill throughput, stripping ratios etc. For each of these variables the user defines an upper and lower limit as well as an ideal target and the system will search for a solution that meets all of the ideal targets if possible, relaxing these constraints if no solution can be found.

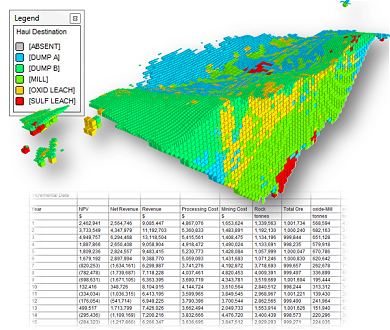

The result is a long term mine schedule which is strategic with respect to NPV, practical with respect to mining shape and pit slope requirements and achievable with respect to the mining equipment fleet and the ore processing capability – in short an optimal combination of maximum NPV within a practical, workable schedule.

In Studio NPVS, the Scheduler produces an OES; in addition to each block having a year number, destination and pushback, each also contains a sequence number that is consistent with the schedule. It is this OES that is input into the Mine Flow Optimizer module (for more information on acquiring this module, please talk to you local Datamine representative).

Note: As Studio NPVS+ scheduler runs always make use of available cores, there is no need (nor is it possible) to add a schedule run to a batch, as in the predecessor Studio NPVS application. You can still batch process the economic model, ultimate pits and pushbacks in Studio NPVS+.

Existing pushback designs can also be imported and scheduled.