Define Stockpiles for the Scheduler

To access this screen:

-

Tasks pane >> Optimization >> Scheduler >> Stockpiles.

Define parameters related to any stockpiled material to be used when generating the schedule.

Once a stockpile is defined you can define the related haulage parameters to compute the truck hours required to transport the stockpiled ore to each of the available destinations, using the Haulage Information wizard.

The Stockpile Destinations tab should be populated after defining Rock Destinations and all Haulage Destinations.

To define stockpiles for scheduling:

Enter a Stockpile Name. This must be unique to the project.

Once a name is set, click Add Stockpile to add it to the current list.

Define Stockpile Content. Enter the currently Stored Tonnage and tonnes per cubic meter Density for the selected stockpile, then Use the Grade table to set up the grade value for each commodity:

The Element list shows elements defined during model import.

The Unit is also as set during model import.

For example, if a product was defined as a Grade element, it may be shown with the Unit of g/tonne. The grade fields are editable and should match the cutoff grade for the stockpile.

Define Stockpile Parameters.

Define the Maximum Reclaim Rate and associated Reclaim Cost. You can set the period after which reclaiming occurs by entering a period number into the Reclaim after period field (the default is zero).

Define Stockpile Economics.

Either use predefined economics for each rock type, as defined using in the Economic Model Settings screen, or you can set up custom economics using your own formula using the Define New Economics option.

- Use Economics of the selected Rock Type allows to select a rock type. The economic parameters for this rock type will apply to the selected stockpile.

Define new Economics requires defining the applicable processing mMethod(s) and related processing costs and product recoveries.

To set up new economics, ensure the previous fields contain accepted values, then (for each Method), click inside the cell for processing cost (Proc. Cos) or one of the available product recovery fields to define a formula using Set Formula.

Note: The Set Formula screen lets you define and check your formula before assigning to the selected method. To remove formula from a field, select it and click Delete Formula.

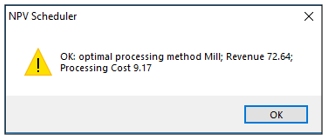

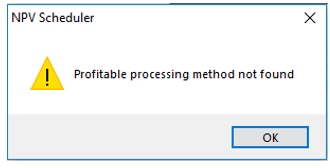

Check your parameters. This identifies potential errors in defining the stockpile plus the processing destination and Revenue/Processing cost per 1 tonne (or ton), for example:

When the stockpiled grade(s) and/or recovery are low Check displays the following warning:

Related topics and activities