Auto Design - Advanced Settings

To access this dialog:

-

Display the Auto Pit Design panel and select the Advanced tab.Display

-

the Auto Dump Design panel and select the Advanced tab.

Note: these settings apply to all pit or dump design scenarios.

Define advanced settings for your automated pit or dump designs. This includes the aspect of the in-pit/dump road to use when setting the automatically-applied gradient values (as defined using the Auto Pit Design tab).

For pit designs, this panel can also be used to define an evaluation legend that can be used to evaluate the theoretical pit phase solid formed by the intersection of an automated design and the topography assigned to the current pit.

Pit Evaluation Settings

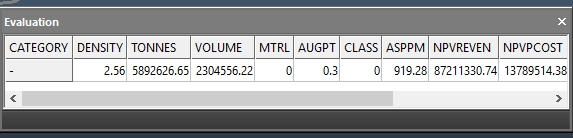

If you choose to automatically evaluate your calculated design surface, results are output to a dedicated Design Evaluation control bar. If no legend is specified, a check is made to see if one has been set up using the Reserves >> Evaluate task instead. If no legend has been configured there either, TONNES and VOLUME (and other attributes) are reported against a single (-) category, for example:

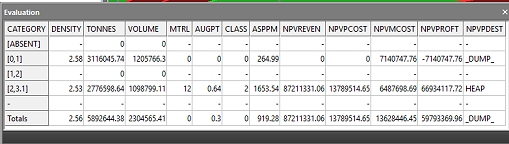

Where an evaluation legend is specified, referencing an evaluation category (either on this panel, or the Reserves >> Evaluate task), categorized results are calculated automatically, as in the following example:

Note: you can't define an evaluation legend when producing dump designs as volume calculations (per-lift) are performed instead, without block model interrogation.

To produce evaluation results (either for pits or dumps), a topography must be associated with the selected pit, and it must be possible to create a closed volume between the generated design surface and the topography. It is the closed volume that is evaluated, so a missing topography will not permit evaluation results to be calculated.

To define advanced settings for all pit or dump design scenarios:

-

Display the Auto Pit Design or Auto Dump Design task.

-

Activate the Advanced tab.

-

Choose how a road's gradient is determined when generated design strings:

-

Steepest—all new projects, or unmodified projects, have this setting by default. This setting automatically determines which aspect of the road segment is steepest and constrains the gradient on that side. This is useful if the projection causes a road to form a complex shape such as an 's', meaning that there is no consistent 'inner' or 'outer' edge. This would also be the case where a switchback has been inserted.

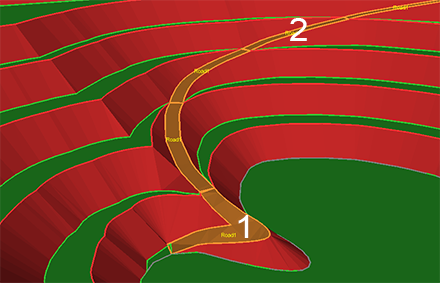

For example, the pit road below is a switchback road from the pit base to the pit rim:

In this example, the goal is to apply a fixed gradient to the entire road of 12 degrees. The inside edge (on the pit void side) of Segment 1 is steeper than the outside, so it is this side to which the gradient setting (12 degrees) is applied. Segment 2 is the opposite; the outside is steeper than the inside edge, so the gradient is applied to the outside edge.

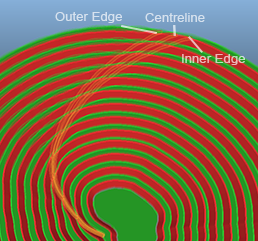

These settings will impact the way adaptive roads are positioned, for example, the following image shows the same road positions calculated by only changing the Road Gradient Side setting:

In comparison with simply setting the gradient to the outside edge consistently, for example, the Steepest option always sets the gradient on the steepest side.

-

Pit inside for Bottom-Up. Pit Outside for Top-Down—choose a road side for gradient constraint depending on the direction the pit or dump is generated; inside for bottom-up designs and outside for top-down designs.

-

Pit/Dump Inside—fix the road gradient on all road segment edges that are on the pit void side or the dump face side, regardless of whether the pit is projected upwards or downwards.

-

Pit/Dump Outside— fix the road gradient on the pit wall side or the air side of the dump, regardless of projection direction.

-

Centreline: set the road gradient at each road segment's centreline.

-

- Gradient Search:

for gradient fitting, define how close a fit you find acceptable,

or how many attempts to make to find the best fit gradient for your

road. A search is performed to find

the best fit for your road and gradient (plus any other constraints)

and a maximum number of iterations is performed to find the optimal solution

- stopping where all parameters have been satisfied.

- Tolerance—how close the defined gradient must be to the specified constraint (e.g. your operational setup may permit a tolerance of +/- 0.25 degrees. Smaller tolerances tend to produce longer calculation times.

- Max. Iterations—how long do you want to spend finding the optimal solution? Increasing this number may increase processing time, but may also lead to a result that more closely matches gradient constraints.

If a gradient is not found (at the required precision)after the maximum number of iterations has been reached, the best solution found so far is used, and a message is sent to the Output bar outlining the road, elevation, and the quality of the final fit, for example:

Road Error: Road1 gradient could only be matched to an error of 5.02628 degrees between elevations 0->20

-

Choose the legend and data attribute used for phase volume Evaluation.

This legend is used in preference to any other evaluation legend configured within the current project (say, as part of reserves evaluation). Hence, it is referred to as an 'override' legend.

Tip: use the Pit Data control bar to display your planning model to quickly review your evaluation legend to make sure it is fit for purpose.

To force a particular evaluation legend to be used, check Override Default Legend, which enables the following options:

-

Legend—select a legend that represents evaluation categories for the selected Column (see below). You can also select <none>, which will report only the accumulated total TONNES and VOLUME for the generated phase volume.

-

Column—select the numeric data attribute that will be evaluated. If <none> is selected, summary TONNES and VOLUMES are calculated for the phase volume.

-

-

Choose whether to use Use full cell evaluation or not:

-

if Use full cell evaluation is checked, model cells are considered to be wholly inside or outside the wireframe. If a cell has more than 50 percent of its volume inside the wireframe it is treated as being included and all its volume is evaluated. This is the quickest approach but is less accurate that permitting partial cell evaluation (see below).

-

If Use full cell evaluation is unchecked, partial cell evaluation occurs, meaning partial cells within the wireframe contribute to an evaluation tonnage or volume. This is a more accurate evaluation method, but slower than the full cell evaluation approach (see above).

-

-

Choose a Projection Method to control how toe and crest strings are rounded. For example, you may want tight curves in these strings to be more angular (say, to represent shapes more fitting for blast design) or more curved (to represent tighter curves more smoothly).

Related topics and activities