RECMODEL Process

To access this command:

- View the Find Command screen, select RECMODEL and click Run.

- Enter "RECMODEL" into the Command Line and press <ENTER>.

See this process in the Command Table.

Process Overview

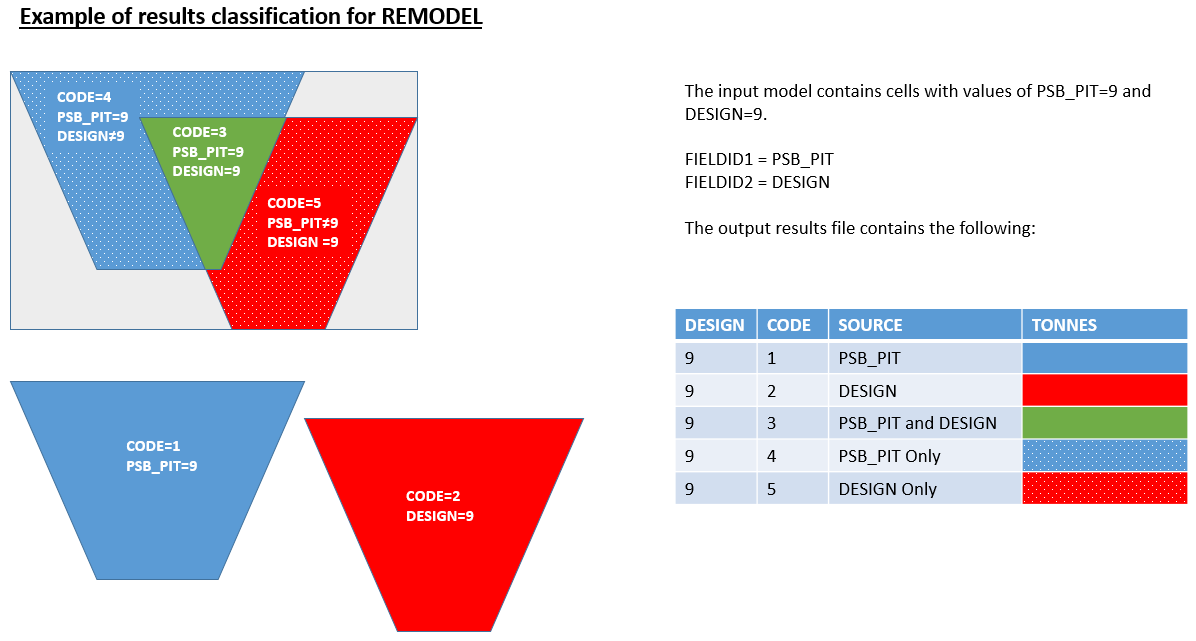

RECMODEL is used to compare the tonnes and grades of pairs of groups of cells in a block model with the same value of two ID fields. An example of how it might be used is to compare the optimised pushbacks defined in a block model against designed pushbacks defined by another set of field values.

Input Files

MODEL File

Input model file for reconciliation. It must contain a field identifying the cells to be reconciled with the wireframe volumes.

For example, if the model has been created by NPV Scheduler this field may be the optimally planned pushback identifier PSB_PIT or PIT_NO. The wireframe files could represent the planned pushbacks. The results would provide an indication of how close the designed pushbacks are to the optimised pushbacks.

Output Files

Results

Output results file containing tonnes and grades for categories of each unique value of IDFIELD2. The categories, with value of RECCODE from 1 to 5, are as follows:

CODE=1, SOURCE=IDFIELD1:

The total amount of material in the model with a specified value of IDFIELD1.

CODE=2, SOURCE=IDFIELD2:

The total amount of material in the model with a specified value of IDFIELD2.

CODE=3, SOURCE=IDFIELD1 and IDFIELD2:

The total amount of material in the model with the same specified value of IDFIELD1 AND IDFIELD2.

CODE=4, SOURCE=IDFIELD1 Only:

The total amount of material in the model with a specified value of IDFIELD1 and NOT with the specified value of IDFIELD2.

CODE=5, SOURCE=IDFIELD2 Only:

The total amount of material in the model with a specified value of IDFIELD2 and NOT with the specified value of IDFIELD1.

Input Files

|

Name |

Description |

I/O Status |

Required |

Type |

|

MODEL |

Input model file for reconciliation. It must contain a field identifying the planned cells to be reconciled with the wireframe volumes. If the model has been created by Studio NPVS or Studio NPVS+ this field may be the optimally planned pushback identifier PSB_PIT. |

Input |

Yes |

Block model |

Output Files

|

Name |

I/O Status |

Required |

Type |

Description |

|

RESULTS |

Output |

Yes |

Results |

Output results file containing the reserve comparisons. This contains up to 5 records for every separate reconciled volume: Total Planned, Total Mined, Planned and Mined, Planned Only and Mined Only. Volumes are defined by the PLANNED and MINED fields and can be further broken down by the KEY1 field and BENCH parameter. |

Fields

|

Name |

Description |

Source |

Required |

Type |

Default |

|

PLANNED |

Field in MODEL file used to group the planned blocks. If comparing wireframe designs with pushback reserves in a Studio NPVS or Studio NPVS+ model this field may be PSB_PIT. |

MODEL |

Yes |

Any |

Undefined |

|

MINED |

Field in the WIRETR file defining the volumes to be compared to the corresponding PLANNED block model cells. |

WIRETR, MODEL |

Yes |

Any |

Undefined |

|

KEY1 |

Optional Key field in the MODEL file used to categorize results (for example, a rock type field). |

MODEL |

No |

Any |

Undefined |

|

DENSITY |

Density field in the MODEL file used to calculate tonnages. |

MODEL |

No |

Any |

DENSITY |

|

GRADE1-10 |

Grade field in the model file |

MODEL |

No |

Numeric |

Undefined |

Parameters

|

Name |

Description |

Required |

Default |

Range |

Values |

||||||||||||

|

VALUE |

Value of PLANNED and MINED fields to compare. If undefined or zero then all values of MINED field will be compared. |

No |

Undefined |

Undefined |

Undefined |

||||||||||||

|

MODLTYPE |

Type of wireframe model to be filled; one of the following options, with default of (1) :-

|

Yes |

1 |

1, 6 |

1,2,3,4,5,6 |

||||||||||||

|

FACTOR |

Scaling factor to adjust the units of the Volume and Tonnage in the output files. Volume and Tonnage are divided by this factor. |

No |

1 |

Undefined |

Undefined |

||||||||||||

|

SETABSNT |

Set to 1 to allow TONGRAD to internally reset absent grade and density values. If this is used, absent grade values are set to their default values. If the default value is absent grade values are set to zero. If density values are absent the default DENSITY parameter value is used." |

No |

0 |

0, 1 |

0, 1 |

||||||||||||

|

BENCH |

Set to 1 to categorize the reserve comparisons by benches.

|

No |

0 |

0, 1 |

0, 1 |

Example

!RECMODEL &MODEL(phasemodel),&RESULTS(recmodel_res),*IDFIELD1(PSB_PIT),

*IDFIELD2(PHASE),*KEY1(ROCKCODE),*DENSITY(DENSITY),

*GRADE1(AU),@FACTOR=1.0,@SETABSNT=1.0,@BENCH=0.0

... Input model: phasemodel

... Default DENSITY value : 1

... Block Model Field identifier: PSB_PIT

... Wireframe Field identifier: PHASE

... Counting number of PSB_PIT values in model phasemodel

... 8 unique values of PSB_PIT found in model phasemodel

... Identifying cells for PHASE 1 (Number 1 of 8)

... Calculating reserves in the Design

...

Related topics and activities