EOM ROM Report

To access this dialog:

-

Activate the Reports ribbon and select Reports >> ROM.

-

Run the command "eom-rom-volume".

-

Use the quick keys 'erv'.

Generate a survey report and corresponding wireframe representing a stockpile volume for a given reporting period. Commonly the volume calculation will relate to the full volume of the stockpile, although a report can be generated for any two (most likely subsequent) stockpile surfaces.

This facility is only available for open pit survey scenarios.

Note: This tool supports batch processing: use Add to Batch to schedule processing at a later date, using the Run Batch task.

Defining Stockpiles

Before you generate a stockpile volume report, you must have at least one string object in the survey database that represents the base string for each stockpile you wish to report. For multiple stockpiles, this string data must contain the following attributes:

- ROMNAME: the name of the current run-of-mine surface upon which the stockpiles are positioned.

- STKNAME: the name of the stockpile. For each unique STKNAME value, a separate volume will be reported.

Note: A stockpile boundary string must be specified to generate an EOM ROM report.

For example, the Stockpile Boundary data file may contain two closed strings; the first is represented by the ROMNAME of "ROM1" and a STKNAME of "Stockpile_1". The second is also determined by a ROMNAME of "ROM1" (they both share the same base surface) and a STKNAME of "Stockpile_2". The resulting report contains volume calculations for both stockpiles independently based on the difference between the specified ROM Base Surface and ROM Stockpile Surface.

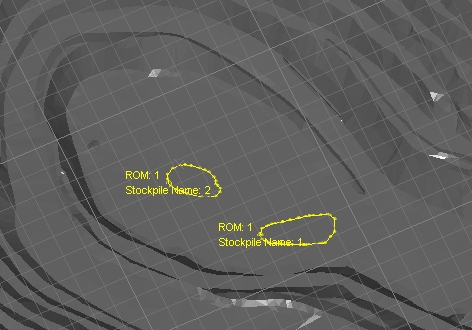

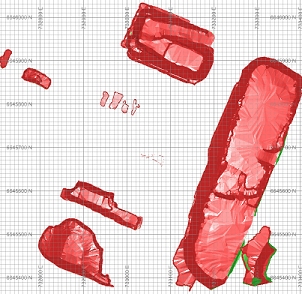

For example, the image below shows a ROM

Base Surface and ROM Stockpile

Boundaries.

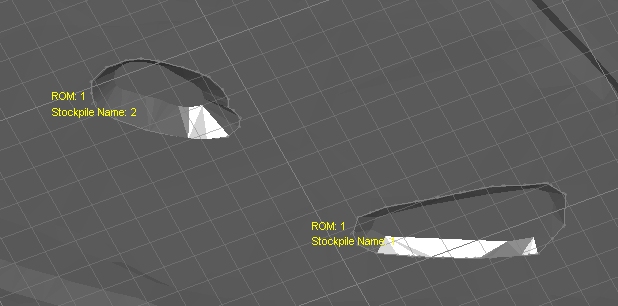

The ROM Stockpile Surface

for this example report looks like this (same string object as above

is shown overlaid):

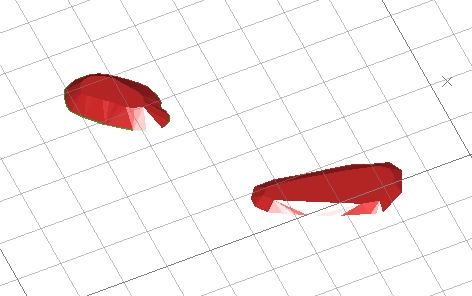

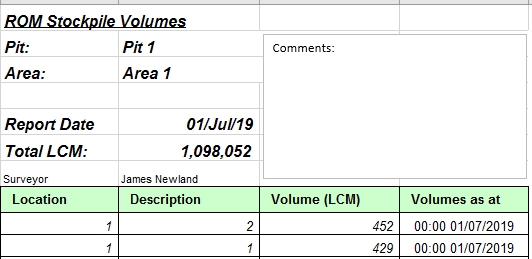

The volumes generated by the ROM report in this example are:

Once published, the report shows

separate volume calculations independently for each stockpile:

Report Output File Naming Convention

Output files from Studio Survey's reporting processes follow the same file naming convention. This is adopted to make files more easily recognizable outside of Studio Survey, and to make searching for them easier.

The following conventions are used

for reports:

Open pit

scenarios:

Report_<pit>_<area>_<rom>_<date>.xlsx

For example:

Report_Pit_1_Area_1_ROM_1_2020-03-23.xlsx

The following conventions are used for output data:

Open pit scenarios:

<data type>_<pit>_<area>_<rom>_<date>.dm

For example:

NaturalSurface_Pit_1_Area_1_2020-03-24_tr.dm

Generating a ROM Report

Providing you have added two surfaces (representing the base and current stockpile surface) and a correctly-formatted string file (containing both STKNAME and ROMNAME attributes and corresponding values) to the databases, you can generate a ROM report containing summary and per-bench results, according to the bench definition for the reporting scope.

- Select the ROM Stockpile Surface by selecting its associated survey date in the drop-down list.

- Select the ROM Base Surface, again by selecting its associated survey date.

- Select your ROM Stockpile Boundary's survey date. To restrict calculations to a single attribute/value pair (each a single stockpile), select the attribute (e.g. STKNAME) and the value to report (e.g. "Stockpile_1"). If an attribute/value pair is omitted, stockpiles will be considered distinct based on their unique STKNAME value, and a volume report will be generated for each.

- Click Calculate to generate the stockpile volumes and associated reports.

Report Output

When you have defined the surfaces you wish to use during reporting of end-of-month results, click Calculate to generate the corresponding volume data. This data will be used to generate an end-of-month as-mined volume report on a bench-by-bench basis.

Report generation includes the following items:

- A spreadsheet containing a ROM EOM worksheet. This worksheet is explained in more detail here.

- A wireframe file pair representing the cut-and-fill volume(s)

between the ROM Base Surface

and the surveyed ground data, e.g.:

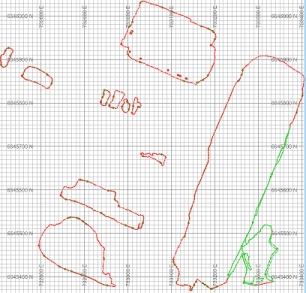

- A strings object containing outline strings for the generated

stockpile volume, e.g.:

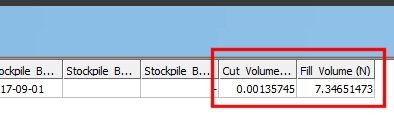

- A Datamine table containing volume calculations for the ROM.

This table is used during publishing to create or update the output

results spreadsheet.

This table will contain two numeric attributes; Cut_Volume and Fill_Volume, representing the cut and fill volumes for the current report, e.g.:

- A copy of any boundary strings used to constrain output volumes.

Using the Reporting Date Calendar

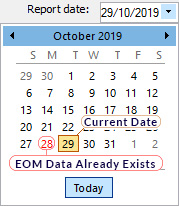

When you select a date for reporting, the calendar tool can be used to see previous report date(s). These are highlighted in red, e.g.:

You can regenerate EOM data for any date, including dates for which EOM

output already exists but, in this scenario, you will need to confirm

if you wish to overwrite existing data.

Previewing and Loading Report Data

EOM reporting panels offer functions to preview both your report input surfaces/strings and your output volumes and reports/tables.

- Preview data: available for all report inputs represented by 3D data.

- Load data: available for all report inputs represented by 3D data, including output data.

If results data is previewed, up to three separate displays will be created:

- A PDF or .emf report: this is generated based on the current Plot Template that is associated with your project. Only displayed if it is possible to generate an output report in this format. Not seeing a PDF or .emf report? Check to see if your report has an associated plot template, using the Database Settings screen.

- Wireframe Volume: this represents the cut & fill solids created by your reporting task. This is shown in Datamine's Table Previewer application. Only displayed if it is possible to construct a 3-dimensional volume from the input data of your report.

- A Report Table: this table, in Datamine format, contains the volume assessment of your cut & fill volumes for the selected report. If it is not possible to construct a 3-dimensional volume, a table (nor any other output) will be displayed.

Configure EOM ROM Report Activity

To configure an EOM ROM report:

-

Ensure the ROM associated with the current project is available for selection, using the Database Settings screen.

-

Open the EOM ROM task and pick the ROM Stockpile Surface (current). This is the ROM to which the current report relates. You can either pick an existing ROM or access the settings dialog to modify the roms of the current database.

-

If you are analysing the change in volumes between two subsequent reporting periods, you can (optionally) choose ROM Stockpile Surface (previous). By default, this is set to <none>, meaning the stockpile volume is ascertained from the current surface and the base surface.

Note: Both current and previous ROM surfaces are added to the database as a Stockpile Surface type.

-

Select the Surveyor for the current report. Surveyor names are configured using the Survey Database Settings task. The Surveyor is displayed in the output end-of-month results, and will appear in the generated spreadsheet report once published.

-

Choose the Report Date. This is the date to be associated with filing the report. By default, this will be the current date. This information is stored in the output wireframe triangles file generated by the reporting process (according to cut and fill calculations), and will be shown in the accompanying published spreadsheet.

Note: You can generate multiple reports on the same day if you need to; each report will be labelled according to the time it was generated.

-

Choose a ROM Stockpile Surface. Select a date that corresponds to ground data for one or more stockpile surfaces. This will be used to define all volumes for all stockpiles in comparison with the ROM Base Surface. Each stockpile will be denoted by its corresponding Stockpile Boundary, as defined within the string object selected below.

Note: Items of the type ROM Stockpile Surfaces must be added to the current database with an associated survey date in order for that date to be selectable.

-

Choose a ROM Base Surface. This is the base surface to be used for ROM volume calculations. As above, ROM Base Surfaces are added to the database using a specific data classification.

-

Choose your ROM Stockpile Boundaries. Select any loaded string object. This object must contain at least one closed string boundary and the attributes ROMNAME and STKNAME to define the base string of each stockpile to be evaluated during cut and fill.

Note: Items of the type ROM Stockpile Boundaries must be added to the current database with an associated survey date in order for that date to be selectable.

You can also generate a ROM stockpile boundary and add it to the current database using the Add Stockpile Boundary managed task. This task allows you to digitize a boundary or select existing string data and assign it to the database as a ROM stockpile boundary.

-

Choose your cut and fill Calculation Options. These determine how data fragments and noise are detected when calculating a cut and fill volume.

-

Remove solids with volume below: by default, all cut and fill volumes that represent the difference between the specified surfaces (optionally constrained by a boundary) will contribute to the output EOM report. You can change this number to remove trivial fragments below a specified volume, with higher values leading to potentially greater volume removal where multiple small volumes are output.

-

Trim solids with thickness below: reduce the number of thin data fragments result from near-coincident surfaces by increasing this value. Higher values will tend to increase the amount of data removed from the output cut and fill solids and resulting report.

-

Decimate input surfaces to limit triangles to: ground data can be represented by very dense wireframe data, and this can lead to increased cut and fill calculation times. Enabled by default, input surfaces will be pre-decimated to reduce their data density and commit less dense/simplified data into the EOM volume calculation routine. This can increase the performance of the EOM reporting tool at the sacrifice of input surface detail.

-

-

If you wish, you can Use a fixed plot scale. If checked, all plotted items will honour the scale set. This can be useful if projections on your report relate to the same data in different views, for example.

-

Define the default Density for your evaluation results.

-

You can also set up a batch run of reports:

-

Finally, review the results of the calculations:

Results:

Add to Batch: add the current report definition to a queue of batched tasks that can be run later using the Run Batch task. Data will not be processed until the batch is processed, meaning changes made to data between report specification and execution will be included.

Related topics and activities