3D Stackers

CHASM supports several different stacking methods, which correspond to the more common types of physical stackers in use at various bulk material handling operations.

Conical

A single conical stack as if the stacker is stationary and continues to pour material at the same spot.

Step

A sequence of single conical stacks, which stack to a predetermined height, then move along a small increment, and repeat until finished.

Chevron

The stacker pours in 'layers' back and forth between two distant points, building up the stockpile until the desired volume or height is reached.

Windrow

A sequence of chevron stackers aligned side by side.

Front-end Loader

A general-purpose stacking mode which uses a quadrilateral shape to describe the four corners of the top of the quad.

When using a front-end loader to stack material, the four corners must:

- Form a convex polygon (example below)

- Not be co-incident (that is, no two points can have the same co-ordinates)

- Be sorted in a certain order (to form the polygon)

- Be co-planar (that is, the four points must lie on the same plane)

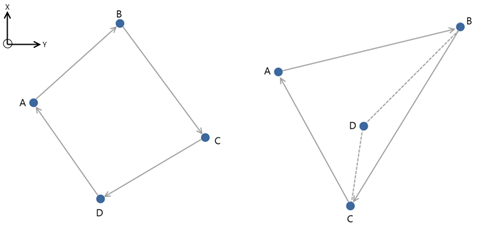

The diagram on the left below is a convex polygon. The diagram on the right below is a concave polygon.