Basic Reconciliation

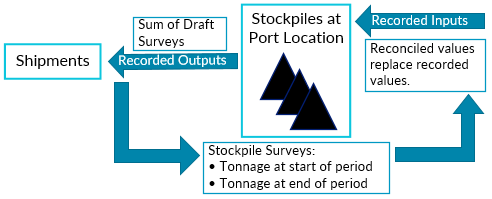

At the end of a reconciliation period, the tonnages of shipments are added using the draft surveys of the vessels at the port location.

By using the surveys of the stockpiles at the port location at the beginning and at the end of the reconciliation period, the Reconciliation Module calculates the total amount stacked in the stockpiles for the specific period:

(Amount Stacked in the Stockpiles at the Port Location) = (Closing Balance of the Stockpiles at the Port Location) - (Opening Balance of the Stockpiles at the Port Location) + (Sum of the Draft Surveys)

This amount is compared with the recorded amount, and then taken as a true value.

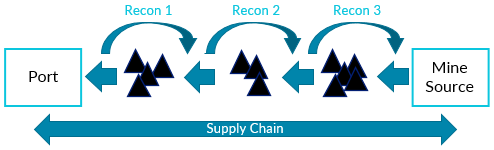

This process of replacing the inputs of a stock location is repeated for each stock location in the business area in the supply chain, going from the port back to the mine sources.

Reconciliation Process at a Port Location

- Reconciliation Value = Closing Tonnages of Stockpiles (Surveys) - Opening Tonnages of Stockpiles (Surveys) + Sum of (Draft Surveys) of Shipped Material

- The reconciliation value is compared with the input tonnages of the stockpiles at the port location (that is, the sum of the transactions that stacked material in the stockpiles at the port location during the period).

- The reconciliation value replaces the recorded value of outputs.

Reconciliation Process along the Supply Chain

The reconciliation process along the supply chain is started at the port location.

- Reconciliation Value = Closing Tonnages of Stockpiles (Surveyed) - Opening Tonnages of Stockpiles (Surveyed) + Sum of Tonnages Reclaimed from the Business Area Location

- The reconciliation value is compared with the recorded sum of the inputs at the business area location (that is, the sum of the transactions of stacked material in the stockpile at the business area location during the period).

- The reconciliation value replaces the recorded value.

- Move to the previous business area location in the supply chain, and go back to repeat the process from step 2.