Grouping Locations for Reconciliation

In discussing the process of reconciliation, stockpiles or stock locations were mentioned without defining the terms precisely. MineMarket defines the concepts of business areas, and business area locations (for example, rail sidings, truck locations, barge terminals and port locations). In reconciliation, it is interesting to consider groups of locations within the supply chain.

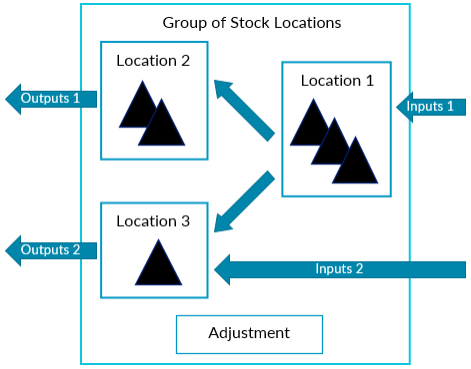

For a reconciliation, process flows coming in and going out from the specified stockpiles can be reconciled. The defined group of locations associated with one reconciliation process can be thought of as one location with one stockpile, such that the opening balance is the sum of opening balances of all stockpiles within the group of locations, and the closing balance is the sum of closing balances of stockpiles within the group of locations. Outputs are transactions going from a stockpile within the defined group of locations to a stockpile outside the defined group of locations. Inputs are transactions coming from a stockpile outside the defined group of locations to a stockpile inside the defined group of locations.

In reconciling a group of locations, the entire group of locations is to be considered, not each individual stockpile within the group of locations.

Problems that Arise When Grouping Stockpile Locations Incorrectly

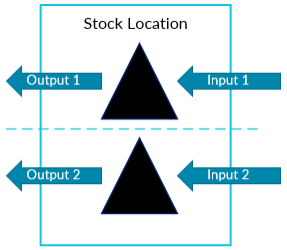

Problems can arise if stockpile locations are grouped incorrectly, leading to incorrect results. Consider a location with two stockpiles, Stockpile 1 and Stockpile 2, with two respective output process flows and two respective input process flows. This location is to be reconciled in a back-push reconciliation, using a ratio of 50% / 50% to spread the inputs.

The following two equations are the result of reconciling this location:

Reconciliation Input 1 = 50% * (Closing Stockpile 1 + Closing Stockpile 2 - Opening Stockpile 1 - Opening Stockpile 2 + Output 1 + Output 2)

Reconciliation Input 2 = 50% * (Closing Stockpile 1 + Closing Stockpile 2 - Opening Stockpile 1 - Opening Stockpile 2 + Output 1 + Output 2)

If each stockpile was reconciled separately, two more accurate equations would have resulted:

Reconciled Input 1 = Closing Stockpile 1 - Opening Stockpile 1 + Output 1

Reconciled Input 2 = Closing Stockpile 2 - Opening Stockpile 2 + Output 2

In fact, the adjustments were spread between the two stockpiles without considering that each process flow targets a specific stockpile. As soon as stockpiles are grouped, individual stockpile reconciliation is of no interest, and only a rough estimate of what is happening in the group of locations is given. If a more accurate evaluation of Input 1 and Input 2 is wanted, consider reconciling each stockpile separately and splitting the group of locations.