MineMarket B2MML Configuration

The Functional Consultant who will configure the supply chain in MineMarket, and the Technical Consultant who will be responsible for deploying the integration, should consider the following topics early in the B2MML implementation.

Note: Words in coloured text refer to node names in the XML file. Words in bold refer to field names or data in MineMarket, or required text strings. Words in italics refer to field values in MineMarket.

Server Configuration

For more information, see the MineMarket Installation Guide.

In the Export category of the MineMarket Server configuration, complete the following fields.

- ExportAssemblyName—Default:

BulkTrak.Integration.Export.dll. This file is provided in the MineMarket Integration Components package. - FilterChangeRegisterObjects—If True, the Change Register database table records the creation/update/deletion only for exportable objects that are registered in the export assembly. If False, every creation/update/deletion of an exportable object is recorded in the Change Register table. Default: False.

- GenerateChangeRegisterObjects—Default: False; however, must be changed to True if the site is exporting data. If a site does not use the MineMarket exporting process, there is no need to generate change register objects. If the export processing never runs, the size of the Change Register table will grow considerably over time and will not be cleared.

Object Event Scripts

Object event scripts are required for stockpiles, despatches and despatch compartments. See MineMarket Object Event Scripts for further information.

Alias1 Values

B2MML includes a concept called hierarchy scope, which is related to the MineMarket supply chain. The MineMarket supply chain includes business areas, locations and stockpile categories. See MineMarket Alias1 Values for information about how these concepts are mapped.

Despatch Routes and Transport Events

If route point times are to be updated for trains and service trips:

- A specific route configuration is required for trains and barges.

- A specific transport event is required for trains.

See Update Actual Route Point Times for a Train and Update Actual Route Point Times for a Service Trip.

Extended Data

The NotifyOperationsScheduled, NotifyWorkExecuted and NotifyWorkReconciled messages store data in the following extended data fields in MineMarket.

- Date7—Timestamp used to determine whether a message contains data that is newer than the current data in MineMarket. Applicable to mine sources, transactions and samples.

- Double1—Volume of material moved in a transaction.

The NotifyPerformanceTracked message exports data from the following extended data fields in MineMarket:

- Date1—On the Sample object, used to store a LIMS date.

- Double1—On the BulkTransaction object, used to store the volume of material moved in the transaction.

To view this data in MineMarket, enable these extended data fields for the required object types. See Specify Extended Data Fields for activity steps.

Export Mapping Configuration

See Map Objects to Third-party Systems for activity steps.

The NotifyWorkScheduled message, used to announce despatch schedules, requires that, for any despatch announced, at least one process flow leading to the despatch loading location be flagged with an export mapping called DefaultWorkScheduleProcessFlow. The value of the mapping is not important. The Alias1 of the flagged process flow is used in the WorkMasterID field of the message.

The NotifyWorkScheduled message requires that when announcing despatch schedules, each barge, train or shipment must have export mappings called JobOrderID and WorkScheduleID. The composite samples, which are created with an object event script only for barges and shipments, must have an export mapping called JobOrderID. Object event scripts assign a unique identifier to each of these export mappings.

When exporting service trip schedules, the MaterialDefinitionID in the NotifyWorkScheduled message can be a customised product name. The Alias1 of the product with an export mapping called BargeScheduledMaterialDefinitionID is used. Only one product can have this export mapping. If there is no product with this export mapping, the text string "Product On Barge" is used.

When exporting shipment schedules, the MaterialDefinitionID in the NotifyWorkScheduled message can be a customised product name. The Alias1 of the product with an export mapping called ShipScheduledMaterialDefinitionID is used. Only one product can have this export mapping. If there is no product with this export mapping, the text string "Product On Ship" is used.

When exporting train schedules, the MaterialDefinitionID in the NotifyWorkScheduled message can be a customised product name. The Alias1 of the product with an export mapping called TrainScheduledMaterialDefinitionID is used. Only one product can have this export mapping. If there is no product with this export mapping, the text string "Product On Rail" is used.

When exporting shipment stockpile states, the MaterialDefinitionID in the NotifyPerformanceTracked message can be a customised product name. For the product with an Alias1 of "Product On Ship" (or "Bauxite Shipped" for backwards compatibility), the value of the export mapping called ShipmentNotifyPerformanceTracked is used. If the product with an Alias1 of "Product On Ship" does not have this export mapping, the text string "Product On Ship" is used.

Export Settings

See Export Data to Third-party Systems for activity steps.

Export settings must enable exporting and include the following exported message types:

- NotifyPerformanceTracked or NotifyPerformanceTrackedPerStockpile—See Export Stockpile and Despatch Stockpile States for more information.

- NotifyWorkScheduledBarge

- NotifyWorkScheduledShip

- NotifyWorkScheduledTrain

B2MML Constraints

The following constraints must be considered when configuring MineMarket:

- If the despatch stockpiles in outbound NotifyPerformanceTracked messages are to be reconciled with those announced in outbound NotifyWorkScheduled messages, each train can have only one rake, and each barge or vessel can have only one hold.

- If a single sampling station is used for multiple destinations, this sampling station must be modelled as a sampling template on a single process flow. This implies that there is a single location as a destination for the process flow on which the sampling occurs. This location must be modelled in B2MML as an area or storage zone.

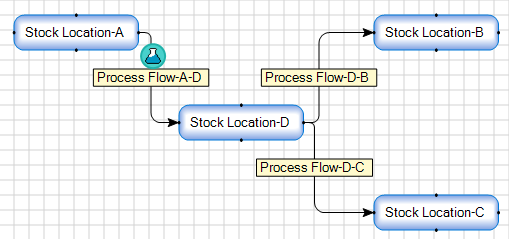

For example, for a site where material is moved from A to either B or C, but goes through a single sampling station, four locations must be modelled in MineMarket and B2MML:

If a SCADA system reports a transaction from A to B, this must be converted into two transactions (A–D and D–B) for inclusion in the B2MML message.