|

|

MAO Haulage Information: Parameter Test Check/test existing haulage parameters |

Haulage Parameter Tests

To access this dialog:

-

Using the Optimization control bar, select Allocation & Flow | Haulage Info... and select the Parameter Tests tab.

This dialog is used to test the viability of currently defined destination, rock type and haulage parameters for a given block location. This is a useful way of validating inputs and calibrating settings before computing truck hours. The purpose of this dialog is to validate the accuracy of all haulage related inputs before generating a schedule.

This dialog allows users to select a particular block, its pushback, rock type, and destination and check the total cycle time plus the equivalent flat haul (EFH) for each of the haulage segments.

The inputs to this calculation are:

- The block XYZ coordinates you wish to test (either in world coordinates or the relative position to the model origin)

- A specific pushback (by index)

- A Rock type as previously defined

- A previously-defined Haulage destination

- The Tonnage (Mass) available at destination

Enter the relevant block coordinates into the fields on this panel and click CALCULATE to generate the Equivalent Flat Haul (EFH distance), for the pushback / rock type / destination / block location between:

- the block location and nearest bench exit.

- the bench exit to the pit exit

- the pit exit and the selected destination exit

- the destination exit and the dump point

|

|

EFH is the distance a truck will travel, under the same load conditions, on a flat haul in the time taken to travel on a specified route profile. See Haulage Analysis for more details. |

Field Details:

Mine name: only available for Multimine projects. Select the relevant mine description above to update the panel with the appropriate options and XYZ range indicators.

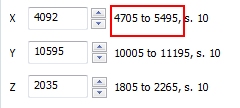

Block Coordinates: enter the XYZ location of a block centroid using either world coordinates, or a local coordinate relative to the block model origin. You can only enter a coordinate that contained within the current mine. This block location will be used to calculate the related EFH distances. I

f you attempt to select a position that isn't

feasible (e.g. it sits outside the ultimate pit) you will be shown

a warning. If using world coordinates, you are shown a valid range

next to the coordinate input field, e.g. in the following example,

you can enter X values between 4705m and 5495m only:

Pushback No.: select the pushback index to which the selected block coordinates are relevant.

Rock type label: select a valid Rock type, e.g. Oxide, Sulfide, Waste

Destination Label: select a Destination as defined in Economic Model settings.

Mass at destination: (where applicable) to define the rock mass delivered to the destination prior to mining of the particular block

CALCULATE: use this button to update results and provide EFH sub-totals for each of the four route components, plus a summary Total.

Details/Results: displayed at the bottom of the panel as read-only information:

-

From block location to the nearest bench exit – shows the EFH (in thousands of meters or feet) from the block to nearest bench exit and return

-

From bench exit to pit exit – shows the EFH (in thousands of meters or feet) for the ramp haul up and down the ramp including its components

-

Gradient factor per bench – shows the gradient factor multiplied by bench height

-

Times bench difference between exits– shows the number of benches between the bench exit elevation and pit exit elevation of the particular block

-

From pit exit to destination exit- shows the EFH (in thousands of meters or feet) for the surface haul to and from the haulage destination

-

From destination exit to dump point– (where applicable) shows the EFH (in thousands of meters or feet) for the two way haul inside the destination

-

Cycle Time– shows the round trip (in minutes) for one truck load

|

|

Related Topics |

|

|

Copyright © Datamine Corporate Limited

JMN 20065_01_EN