Scheduling Setup: External Sources

To access this screen:

-

In the Scheduling Setup screen, select the External Sources tab.

Define external source supply for your scheduling scenario.

Material can be added to a schedule from external sources. External Sources can be used to define:

-

ore available at the beginning of the schedule (similar to stockpile with initial state)

-

ore that will become available later in the mine life (from an underground mine or any other source of ore)

Important: Ore from the pit cannot feed an external source. Ore from external sources can only feed a processing destination.

External Sources can be defined by clicking Manage External Source. The displayed screen allows setting up external sources names and ordering them. You can create a source with + and delete existing ones with x.

Some examples of external sources:

-

Underground mines (the tonnage, cost, recovery, grades will change between the periods).

-

Existing stockpiles that will not accept new ore (the initial tonnage and grades are fixed, the ore will be reclaimed as needed over multiple periods).

-

Other sources for blending (for example CaO needed for cement).

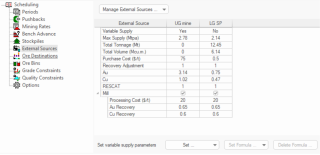

After external sources are added there will be one column for each external source to define their parameters, for example (click to expand):

Variable Supply Costs

External source parameters are, by default, the same for the life of mine.

Variable Supply indicates when an external source has maximum supply, purchase cost, recovery adjustment, or grades that vary in time.

For example, you can determine that your maximum supply rate is different in the first few years of your schedule to the years that follow. Similarly, you can adjust purchasing cost and the recovery cost adjustment ratio, or the adjustment for any other product cost.

Total Tonnage and Total Volume

Total Tonnage and Total Volume apply only to external sources where grades and purchase cost is fixed. This it typical for ore mined in previous periods and available to be included in the new schedule in addition to the new ore that will be mined from the pushbacks.

This is LG SP in the example further above containing 12.45 M tonnes with volume 6.14 M cubic meters, grades 0.75 for Au and 0.47 for Cu, and RESCAT 1. The cost for delivering ore from LG SP to the Mill is 0.5 $/t.

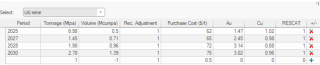

Consider the following example, where UG mine is an external source, where the supply (mass and grades) varies in time. For such external sources Total Tonnage and Total Volume need to be kept 0. Instead clicking Set opens a window where different values can be defined between the periods (click to expand):

Mill is a processing destination where ore from UG mine and LG SP can be delivered if the selection box is checked. Mill processing cost ($/t) and processing recoveries (fractions) are defined for each external source. These can be fixed values or defined using expressions. Selecting a box and clicking Set Formula (see below).

Formulae

Processing costs can be defined explicitly and by formulae. A formula is useful where a value depends on another scheduling variable, such as grade or downstream costs.

Specifying a formula is achieved by clicking into the appropriate table cell, and clicking Set Formula (this is only available for formula-supported cells). Formulae are defined using the Define Formula screen.

See How to Use Formulae.

Create and Configure an External Source

To create a new external source:

-

Display the External Sources screen.

-

Click Manage External Sources. See Manage External Sources.

To define external source settings (static across life of mine):

-

In the External Sources Settings table, for the external source column, review the available settings:

-

Variable Supply—If variable supply parameters are defined for the stockpile, this displays Yes, otherwise No. See "Variable Supply Parameters", above.

-

Total mass – The total mass constraint for the external source.

-

Total Volume – The total volume constraint for the external source.

Note: Volume units correspond to the Measurement system in Default Project Settings, and typically set during block model importation.

-

-

Max Supply—Upper limit on the provision of material from the external source within the mining rate period (either kilotonnes per day or million tonnes per annum).

In other words, Max Supply shows the maximum rate for delivering ore from the external source.

-

Purchase Cost ($)—The additional cost per rock mass unit associated with the purchase and handling of external material.

-

Materials-Set the tonnage and grades of all elements arriving from the external source.

-

Processing Destinations—Each processing destination can have independent stockpiling parameters. Enable the processing destination for a stockpile by checking it.

Once a processing destination is checked, destination stockpile settings are:

-

Processing Cost ($)—The cost attributed for the processing destination, per rock mass unit. This is set as an explicit numeric value or as a formula (see "Formula", above).

-

Material Recovery Costs—For each defined product, what is the associated recovery cost as a value or formula.

Note: An external source must be checked (active) and a Processing Cost or Recovery field selected for Set Formula to become available.

Note: Click Delete Formula to clear an existing formula from a table cell.

-

-

-

To set per-period external source tonnage, volume, purchase costs and product constraints, click Set. See Define Variable External Source Constraints.

-

Save your scheduler settings.

Related topics and activities