Scheduling Setup: Ore Bins

To access this screen:

-

In the Scheduling Setup screen, select the Ore Bins tab.

Define the ore bins for the rock types associated with your scheduling scenario.

Note: Ore bins are also referred to as "grade classes".

Ore bins can be defined either by a single element (the rock type will only ever have one product recovered) or by all products (which could be useful for more general destinations such as leeching or milling, where multiple metals can be recovered).

Ore bins are needed to define the grade resolution details for your scheduling scenario. The rock mass from each pushback bench (a mining block) is sub-divided in parcels created by rock type and the bins for this rock type. More mining blocks and more parcels can increase the processing time but will allow more flexibility when dealing with different grade stockpiles or when blending.

By default Studio NPVS+ creates 25 bins for each rock type and these bins are using all products. The grade range (min and max) is set automatically. The minimum value equals the minimum ore grade for the rock type and product. The maximum is set to 80% of the maximum grade for the rock type and product.

Note: Rock types and products are defined when you import a block model.

For each rock type (either for a selected element or all products) you can define the minimum and maximum metal grade, and the number of bins to make.

With two or more products ore bins are created using block values.

-

Value Min is the value ($/t) for a block with the Minimum Au and Cu grades.

-

Value Max is the value ($/t) for a block with the Maximum Au and Cu grades.

The first ore bin will contain all blocks with value above Value Max. The last (25th) bin will contain all blocks with value below Value Min. The remaining blocks will be distributed within 23 bins between Value Min and Value Max.

Ore bins can be set by one product/element using Bin Type list. Choosing the number of bins, selecting the Element, and defining min/max grades determines the bins and their grade range.

All waste blocks on a pushback bench are separated in a waste bin.

The proportionally mines all bins from a pushback bench and send the material from each bin (parcel) to the destination that will maximize profit considering capacity constraints, mining constraints, bench advance, and so on.

Examples

Example 1

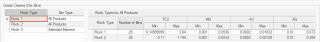

For example, in the image below, a grade class is configured for the "Rock 1" and "Rock 2" rock type that utilize the All Products Bin Type to recover up to four defined metal products (Copper, Molybdenum, Gold and Silver):

(Click to expand)

In the case above, we will make 25 bins recovering from Rock 1, where the following grade constraints are true:

-

TCU—0.1499 to 3.04 g/t

-

MO—0.001 to 0.0536 g/t

-

AU—0.002 to 0.0183 g/t

-

AG—0.01 to 0.672 g/t

A third rock type ("Rock 3") has a Selected Element Bin Type, for gold in the 0.05 to 0.855 g/t range:

(Click to expand)

Example 2

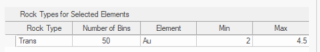

In the example below the ore blocks from Trans rock type will be distributed in 50 bins by Au grade between 2 and 4.5 g/t (click to expand):

To define an ore bin for all products:

-

Display the Ore Bins screen.

-

Review the Grade Classes (Ore Bins) table; all rock types display as a table row.

-

Where a rock type can be processed to recover metals from (potentially) multiple elements, expand the Bin Type list to choose All Products.

-

Review the Rock Types for All Products table on the right.

For each Rock Type, the current Number of Bins expected is set, along with Minimum and Maximum grade constraints for all defined products.

Note: The table displays with identical contents for all ore bins of the All Products type.

-

For each Rock Type:

-

Set the Number of Bins to make.

-

Set the Minimum and Maximum grade constraint for each product (you can set zero for Min and Max to exclude a rock type).

-

-

Save your settings.

To define an ore bin for all a specific element:

-

Display the Ore Bins screen.

-

Review the Grade Classes (Ore Bins) table; all rock types display as a table row.

-

For the Rock Type to have a single element bin constraint, choose the Selected Element Bin Type.

Note: This removes the rock type from all views of the Rock Types for All Products table, and adds it to views of the Rock Types for Selected Elements table.

-

Review the Rock Types for Selected Elements table on the right.

-

For each Rock Type:

-

Set the Number of Bins to make.

-

Choose the Element for which the grade constraint applies.

-

Set the Minimum and Maximum grade constraint for each product.

Note: Set zero for Min and Max to exclude a rock type.

-

-

Save your settings.

Related topics and activities