|

|

Configuring Destinations

To access this dialog use one of the following:

-

Activate the Schedule ribbon and select Setup. Select any destination on the left.

-

In the Scheduling Setupdialog, select any of the items in the Destinations menu group.

About Destinations

Destinations panels are used to add, edit or delete destinations for the scheduled material. Destinations for Processes (plants, leachpads etc.), Stockpiles and Dumps are configured independently, using a dedicated panel.

Destinations are the end points in the scheduling of materials. For example, waste dumps, stockpiles and processing plants.

Material is sent to these locations by the loading activity (optionally via trucks). The main controls within the dialog are constrain by Category to limit which acceptable categories can be sent to the destination, e.g. ore to a plant and waste to a dump.

Processing Capacity controls how much can be sent per period and Maximum capacity is how much the destination can hold in total, normally used only for stockpiles and dumps.

Other options include costs (used for CPLEX Solving) and Constrain by Range and Filter. Range will only allow blocks that fit within allowable limits to be sent whereas Filter should be considered a more free-form methodm allowing you to define a restriction based on any field in the reserves. Filters are normally used to prevent material from certain locations from being sent to the wrong location.

Both Dumps and Stockpiles can be modelled to control in finer detail the location of materials within them. These models are created later in the process. Stockpiles also have an option for external material delivery.

Grade quality targets within destinations allow the user to define a target based on the grade values (value before multiplied by tonnage).

Throughput and Recovery further control the processing rates (per block) and recovery of grades within the automatic solvers.

More Information

Press <F1> in any screen to show context-sensitive help, or use the Table of Contents on the left to refer to a particular topic.

Alternatively, select a link below:

General

settings: displayed on General

tab, these settings are similar for all destination types and

are used to define the name of the destination, capacity limits

and controls, processing costs and constraints. More...

General

settings: displayed on General

tab, these settings are similar for all destination types and

are used to define the name of the destination, capacity limits

and controls, processing costs and constraints. More... Throughput

Recovery settings (Processes): The Throughput/Recovery

tab is used to define optional material throughput and recovery

settings for a process-type destination.

More...

Throughput

Recovery settings (Processes): The Throughput/Recovery

tab is used to define optional material throughput and recovery

settings for a process-type destination.

More... Stockpile settings: define

general details for a stockpile such as its name, the maximum

reclaim and whether to mine the stockpile only after any

available mining block material is depleted. More...

Stockpile settings: define

general details for a stockpile such as its name, the maximum

reclaim and whether to mine the stockpile only after any

available mining block material is depleted. More... Stockpile Supply settings: define

the initial and subsequent periods' material mass, density and

grade/quality settings. More...

Stockpile Supply settings: define

the initial and subsequent periods' material mass, density and

grade/quality settings. More... Stockpile Model settings: define

stockpile model, build and reclaim sequence, initial state, swell

and haulage parameters. More...

Stockpile Model settings: define

stockpile model, build and reclaim sequence, initial state, swell

and haulage parameters. More...-

Dump

Model Settings: define dump modelling files output from

the Dump Evaluation process.

More...

Dump

Model Settings: define dump modelling files output from

the Dump Evaluation process.

More...

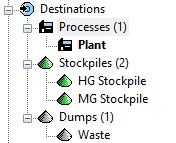

Existing Destinations

Previously defined destinations appear in the menu system on the left, split into Processes, Stockpiles and Dumps, e.g.:

Select an item to show the corresponding properties on the right. Each of the destination types are supported by similar general settings, although type-specific settings (such as dump modelling and stockpile settings) are provided via subsidiary tabs.

Adding a New Destination

-

Right-click either the Processes, Stockpiles or Dumps icon in the menu on the left of the screen.

-

Click Add

-

Use the General and other tabs to define the scheduling destination parameters.

Editing a Destination

-

Use the menu system on the left to select an existing destination, then edit its properties on the right.

Deleting a Destination

-

Right-click an existing destination in the menu on the left and click Delete .

|

|

Related Topics |

|

|

Managing

Calendars Managing Machines Managing Haul Trucks Managing Haul Routes Destinations General Destination Targets Throughput/Recovery |